High-Density Polyethylene (HDPE) sheets have emerged as a versatile and indispensable material in various industries, thanks to their exceptional properties and wide range of applications. From construction and packaging to agriculture and marine engineering, HDPE sheets offer unparalleled durability, chemical resistance, and versatility. Let’s delve into the world of HDPE sheets and uncover their myriad uses and benefits.

Understanding HDPE Sheets

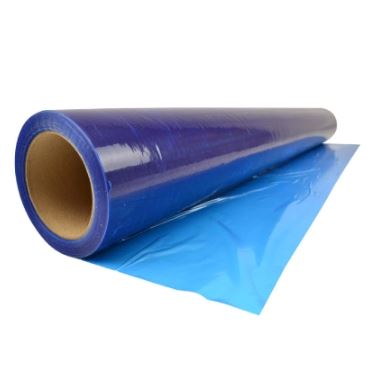

HDPE sheets are manufactured from high-density polyethylene resin, a thermoplastic polymer known for its excellent strength-to-density ratio, chemical resistance, and low moisture absorption. These sheets are produced through a process of extrusion, resulting in flat, thin panels with a smooth surface finish.

Applications Across Industries

Construction:* HDPE sheets find extensive use in construction applications, including wall cladding, roofing, and waterproofing membranes. Their durability, flexibility, and resistance to UV radiation and harsh weather conditions make them ideal for protecting structures from moisture ingress and environmental degradation.

Packaging:* In the packaging industry, HDPE sheets are commonly used to manufacture containers, bottles, and packaging films. Their lightweight, impact-resistant, and recyclable properties make them suitable for packaging a wide range of products, from food and beverages to chemicals and pharmaceuticals.

Agriculture:* HDPE sheets play a crucial role in agricultural applications, such as greenhouse construction, pond lining, and irrigation systems. Their resistance to chemicals, UV radiation, and abrasion makes them ideal for withstanding the rigors of agricultural environments while providing long-lasting protection and containment.

Marine Engineering:* In marine engineering and offshore applications, HDPE sheets are utilized for marine fendering systems, dock bumpers, and boat components. Their high impact strength, corrosion resistance, and buoyancy properties make them well-suited for withstanding the harsh marine environment and protecting waterfront infrastructure.

Advantages of HDPE Sheets

- Durability: HDPE sheets are highly durable and resistant to impact, abrasion, and environmental stressors, ensuring long-term performance and structural integrity in demanding applications.

- Chemical Resistance: HDPE sheets exhibit excellent resistance to a wide range of chemicals, acids, and alkalis, making them suitable for use in corrosive environments such as chemical processing plants and wastewater treatment facilities.

- UV Stability: HDPE sheets are inherently resistant to UV radiation and do not degrade or become brittle when exposed to sunlight, making them suitable for outdoor applications where prolonged exposure to sunlight is a concern.

- Recyclability: HDPE is a recyclable material, allowing for the reuse and repurposing of HDPE sheets at the end of their service life, contributing to resource conservation and waste reduction efforts.

- Ease of Fabrication: HDPE sheets are easy to fabricate, cut, weld, and thermoform, allowing for customization and adaptation to specific project requirements with minimal effort and cost.

Conclusion

HDPE sheets have established themselves as indispensable materials across a wide range of industries, thanks to their exceptional durability, chemical resistance, and versatility. From construction and packaging to agriculture and marine engineering, HDPE sheets continue to play a vital role in protecting infrastructure, enhancing efficiency, and promoting sustainability. As industries continue to innovate and evolve, the demand for HDPE sheets is expected to grow, driving further advancements and applications in the years to come.